Manage inventory

Inventory includes available stock, incoming shipments, and reserved inventory. Real-time tracking prevents overselling, ensures timely restocking, and optimizes supply chains.

An inventory management app enables merchants to query and adjust stock levels across multiple sales channels, ensuring accuracy and efficient fulfillment. Apps and third-party logistics providers can integrate with Genstore’s RESTful API to automate inventory management, including stock queries, adjustments, and warehouse bindings.

This section covers how to use Genstore’s APIs to manage inventory effectively.

How it works

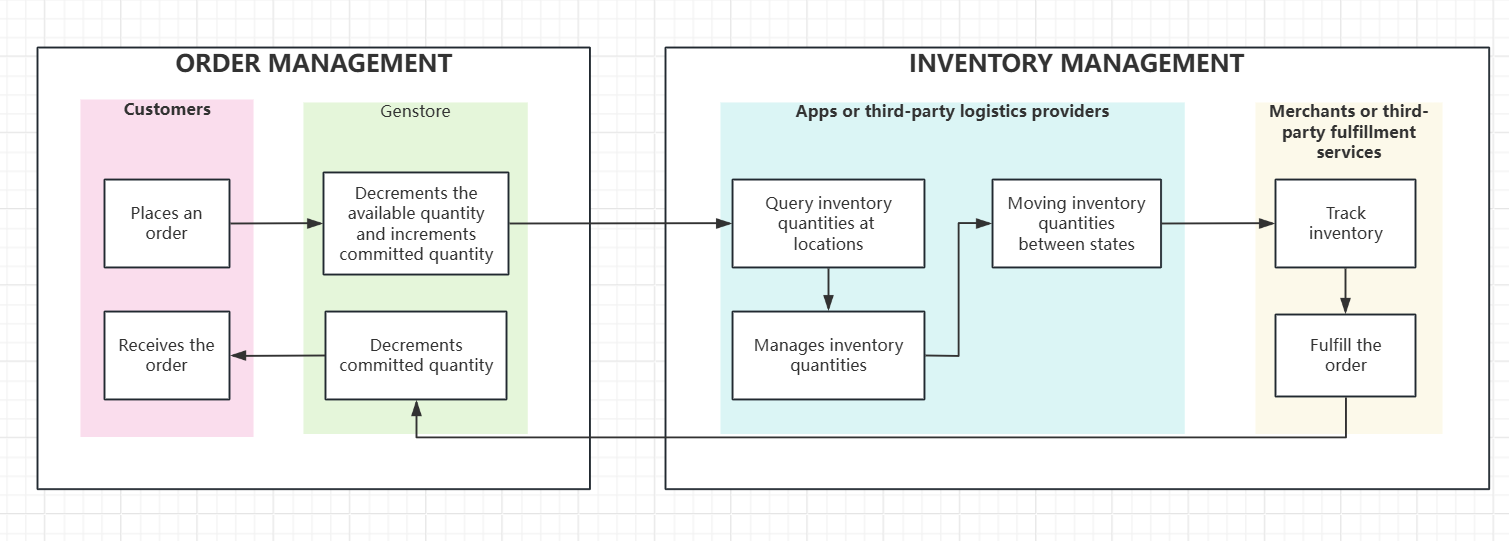

Inventory is a critical component of retail operations, allowing merchants to track and manage stock across multiple locations. The inventory management system includes the following processes:

- Order placement – When a customer places an order, the system deducts the corresponding stock from available inventory and marks it as committed until fulfillment is completed.

- Inventory adjustments – Apps or third-party logistics providers can update inventory levels to reflect real-time changes.

- Warehouse binding – Product variants can be linked to specific warehouses, ensuring inventory data is accurately managed per location.

The diagram below illustrates key inventory management activities within the order lifecycle:

Key entities in inventory management:

- Customer – Places an order containing product variants.

- Genstore – Adjusts inventory levels during order creation and fulfillment.

- Apps/Third-party logistics – Automates inventory tracking and adjustments.

- Merchants/Fulfillment services – Monitor inventory and fulfill orders within Genstore’s system.

Inventory status

Inventory status help merchants track product availability at specific locations. The common inventory states include:

| Status | Description |

|---|---|

| Available stock | Inventory displayed on product pages as purchasable stock, excluding committed stock. |

| On-hand stock | Actual stock in warehouses used for warehouse management, replenishment, and supply chain optimization. - Scenario 1: In pre-order situations, the on-hand stock may be 0, but merchants can still enable pre-orders if restocking is planned. - Scenario 2: In return processing, returned items move to on-hand stock before being resold as available stock. |

| Committed stock | Stock reserved for orders but not yet fulfilled, preventing overselling. |

| Unavailable stock | Inventory reserved for specific customers or temporarily removed from sales, often for quality checks or emergency purposes. |

| Incoming stock | Stock currently in transit and expected to arrive at the warehouse. |

API overview

Inventory management often involves tracking stock across multiple product variants, including different sizes, colors, and attributes. Genstore provides RESTful APIs to manage inventory, supporting operations such as binding, updating, and querying inventory levels.

| API Endpoint | Description |

|---|---|

/api/202412/inventory/connect | Link a product variant to a warehouse |

/api/202412/inventory/{variantId} | Update inventory levels for a variant |

/api/202412/inventory | Query inventory across warehouses |

- The binding API links product variants to a specific warehouse, ensuring accurate inventory tracking.

- The update API modifies stock levels for a product variant, commonly used for order creation and stock corrections.

- The query API retrieves inventory data from warehouses to enable real-time monitoring.

Use cases

Inventory management plays a crucial role in various business scenarios, including:

- Order fulfillment control – Ensures customers see accurate stock levels to prevent overselling.

- Supply chain management – Centralized inventory tracking across multiple warehouses and sales channels.

- Stock alerts and restocking – Monitors inventory levels and alerts merchants when restocking is required.

- Omnichannel sales – Synchronizes inventory across online and offline stores to maintain consistency.

Limitations

Committed stock cannot be adjusted via API. The REST API does not allow modifications to committed stock. This inventory state is only affected by order creation and fulfillment actions. Developers must ensure inventory updates align with the order processing system to maintain accuracy.